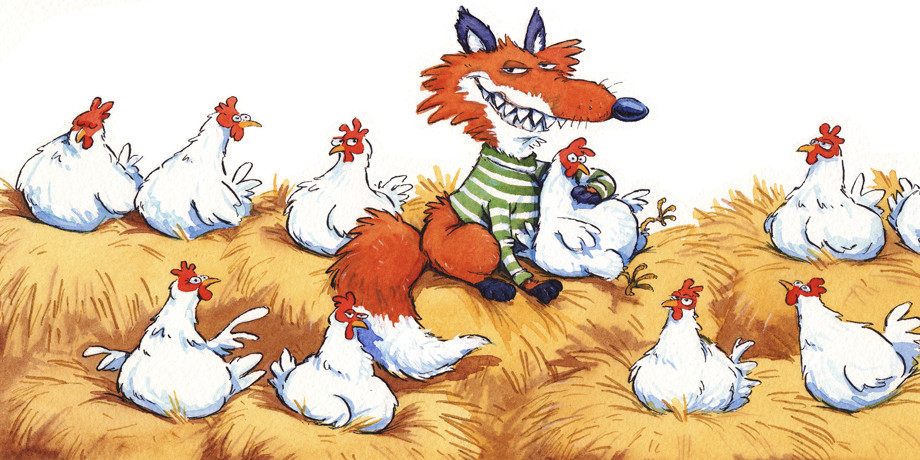

There are foxes in the hen house! A Global Supply Chain Reality

The idiom "The fox in charge of the hen house" refers to the idea of putting someone (the fox) in charge of an activity or process (managing the hens) where they have the opportunity to take advantage of or abuse the results (eating the hens).

For most companies, their global supply chains are a reflection of the age-old parable. I say this because it is the simple reality of the way the global supply chains are set up. All global supply chains have a significant component that is outsourced i.e. suppliers, manufacturers, 3PLs, Carriers, Customs Brokers, Warehouses, etc., etc. In many, if not most, 100% of the supply chain profile is composed of outsourced "partners" - from supply to logistics, to customs and regulatory agencies, to distribution.

So what does this have to do with the idiom? Each outsourced partner in a supply chain is a fox, and you and your company are the hens.

For most, you are thinking that this is a bit of a stretch. But give me a moment to explain how I come to this conclusion.

3 very common challenges for managing global supply chains

When we talk with importers or exporters, we most commonly hear the following 3 challenges for managing their global supply chains:

1) Little or no Supply Chain visibility - They have little or no visibility as to where their product is in the global supply chain. To get the information they are reliant on their 3rd parties, whether they are suppliers or service providers. If they need visibility, they are dependent on these outsourced partners to provide it. For most, they have neither the systems in place to monitor their execution in real-time nor the ability to understand their historical performance.

2) Invoice and cost accuracy is a problem - They have little or no capability to monitor the accuracy of the invoices for product or service. In complex invoicing environments, such as freight or customs brokerage, they often can't manage the auditing of invoices. Study after study shows that errors occur on invoices, and that these errors are almost always to the advantage of the supplier or 3rd party service provider.

3) Global Supply Chain analysis is less than optimal - Information on the activity in the global supply chain is most often maintained at its source and not aggregated into a central repository. The dispersion of data across multiple actors, related to a single SKU in the global supply chain, results in poor synchronization, quality, accessibility, and visualization of information.

I recognize that there are companies that have and exercise some control over their supply chains. However, like in all things very few dominate their area. And when it comes to the supply chain, Walmart, Amazon, Apple, GE, and others are among those constantly mentioned as paragons of supply chain excellence. What is common to these 'paragons', and others like them, is that they have invested very heavily in building the infrastructure to monitor, manage, and gain control over their global supply chain through information systems that provide consistent, timely, and accurate information. Through this information, they have visibility and context of their supply chains and are able to make informed decisions and be proactive.

Visibility and context give these paragons of the supply chain control over their supply chains, and by extension, their suppliers and service providers. Supply chain transparency delivered through accurate synchronized information provides them powerful influence over their 3rd party actors to achieve optimal results. These companies know what to expect from their supply chain partners, and most importantly, their supply chain partners know that they know. These global supply chain paragons hold their supply chain partners to account because they control the information.

These paragons see the results through the highest levels of supplier fulfillment (purchase order accuracy and fulfillment), on-time shipping and transportation performance, total lowest landed cost of a product, highest levels of customs and regulatory compliance, lowest levels of supply chain risk. By controlling their out-sourced agents, they get exceptional results.

The bottom line is that when companies have the tools to manage and control their global supply chains they eliminate, wherever possible, the opportunity for their outsourced "partners" to take advantage of them - advertently or inadvertently. With the right controls, they are not prey to the foxes that would manage their hen house.

Walmart, Amazon, Apple, GE spend millions building up their supply chain infrastructure to allow them to have control. They are constantly looking for supply chain advantage by unfailingly monitoring, reporting and analyzing their outsourced partners and demanding improvements and results.

Now, this global supply chain information infrastructure is available to any company with a global supply chain. Solutions like 3rdwave, simplify global trade by providing the execution platform for capturing information and delivering visibility, reporting, and analysis of the global supply chain. These capabilities allow companies to control their information and enable organizations to strongly influence performance by their outsourced partners and dramatically improve outcomes.

You can, and should, control your hen house. If you aren't in charge of your hen house, you are at a major and growing disadvantage.