“I often use brass hinges, screws, and pulls in my work. I know I can buy products with various antique effects, but how can I customize my own colors and finishes on brass hardware?”

“I often use brass hinges, screws, and pulls in my work. I know I can buy products with various antique effects, but how can I customize my own colors and finishes on brass hardware?”—Regan Lumley, Henderson, NV

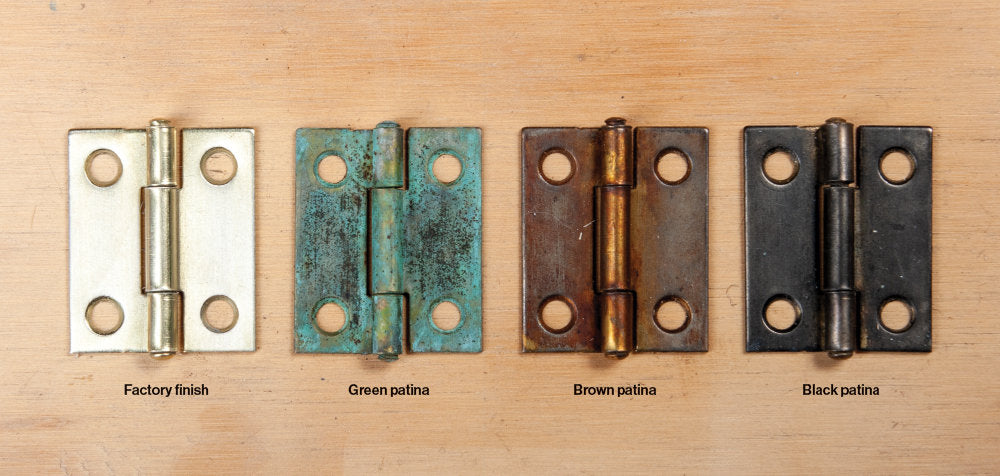

One of the more fun and foolproof methods of adding color to metal is through the process of patination or chemically oxidizing a metallic surface to change its color. Patinas develop naturally over time when metal is exposed to the elements, as in the case of green copper roofs or dark brown bronze statues. But by applying a few different chemicals, we can expedite this process and control the color. Some commercially available patina solutions come premixed so that achieving a particular color is as easy as following the directions on the bottle. And there are methods of using common household chemicals that work well. But neither allow much customization of the end result.

I prefer mixing my own patinas from crystalline solids that are easily diluted in water and can be mixed together to achieve a multitude of different colors. I’ve included a few staple recipes here, but if you want to experiment further, check sciencecompany.com for additional recipes and safety info.

To start, ensure that the surface of the hardware is clean, which includes removing any clear coating applied by the manufacturer. I recommend soaking the hardware in acetone and then scrubbing the lacquer off with a brass wire brush. Patina recipes typically indicate whether they are a hot or cold application, meaning that the surface of the hardware needs to be either heated or left at room temperature before application. For hot applications, warm the hardware with a propane torch or heat gun on a fire-safe brick, or simply leave it in the sun for a few hours on a hot day.

Once the hardware is prepped, it’s time to apply. Working in a well-ventilated area and wearing vinyl or nitrile gloves, mix your desired patina solution and use a bristle brush to paint a thin layer onto the hardware. Let it dry before applying another coat. Repeat this process until the desired color is achieved. If you don’t like the results, you can sand it off and try a different solution. Keep experimenting until you reach a patina you prefer. To finish, buff the surface with a white scotch-brite pad and seal your custom creation with lacquer or wax.

Three common formulas

These three basic mixes will get you started customizing brass hardware, but you can also experiment to see their effects on other metals. Some patinas work better on copper alloys, such as brass and bronze, while others work better on steel or nickel.Green patina

1 tsp cupric nitrate

1 pint distilled water

hot application

Brown patina

1⁄2 tsp ferric nitrate

1 pint distilled water

hot or cold application

Black patina

1 tsp sulfurated potash (liver of sulfur)

1 pint distilled water

hot or cold application

Crystalline solids can be purchased through sciencecompany.com (see Buyer's Guide, below).

Painting patina. Handle heated hardware with pliers or tongs and apply patina with a natural bristle brush. Drive screws into scrap wood to secure them before patinating their heads to match the hardware.

Buyer’s Guide

Sophie Glenn is a metal worker, woodworker, furniture designer, and sculptor based in Reading, Pennsylvania.