Bypass Oil Filtration to Preserve the Engine

In the late 1960s, as a budding light and medium duty fleet truck mechanic, I maintained a fleet of 1949-61 trucks. The OHV 235 and 261 inline six-cylinder Chevrolets, the ’49 GMC Jimmy 270 and several International-Harvester BD240 sixes relied on bypass oil filtration systems to protect the lubricated engine parts and clean the oil.

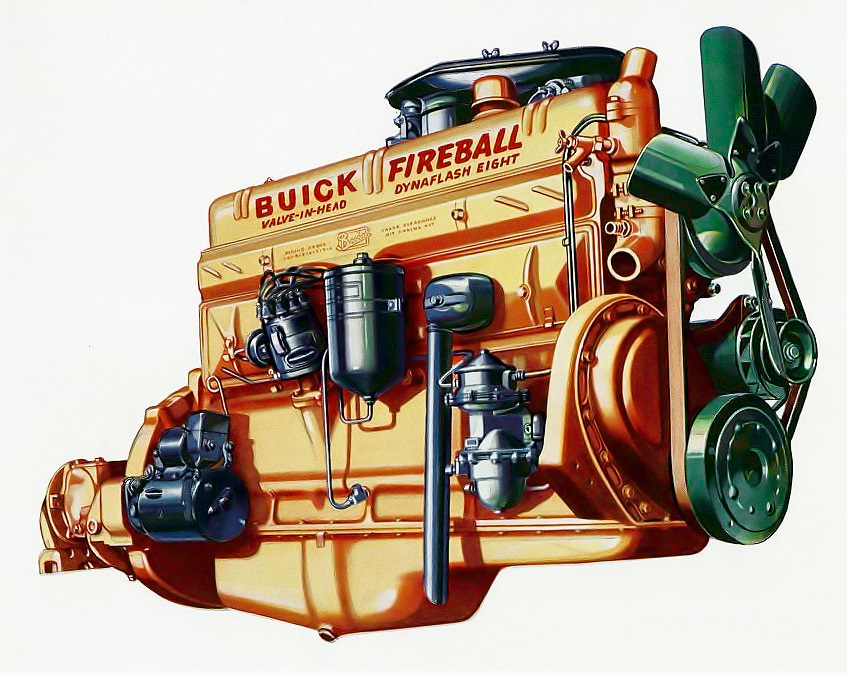

Bypass oil filtration was not new when John Frantz brought his filter to market in 1953. However, bypass filtration was often an option (not standard equipment) from vehicle manufacturers. Between 1936 and 1952, Buick’s Fireball Eight OHV inline engine was a legend. Last offered in the 1953 Buick Special, the straight eight featured a bypass oil filtration system. The filter canister is mounted to the engine beside the ignition distributor.

While the 1955-up Chevrolet small-block V-8 was also a legend, the first year engine did not have a full-flow oil filtration system. Seen here in this painstakingly restored ’55 Bel-Air convertible, the 265 V-8 boasts the optional bypass filtration canister (blue and orange unit) mounted atop the intake manifold. The same bypass filter was also offered in light truck models. 1956 saw the first small-block (still a 265) with a full-flow oil filter stand cast into the engine block. The Frantz retrofit bypass oil filter was popular by the mid-fifties.

The truck fleet also had 1958-60 F100 Ford pickups with 223 OHV sixes and “full-flow”, spin-on oil filters. The full-flow filter was a breakthrough in engine filtration, touted for its ability to filter all of the oil that left the oil pump and headed to the engine bearings. The engines with bypass filtration relied solely upon the mesh pickup screen at the oil pump to catch debris. Unfiltered oil went from the oil pump to the galleys and bearings. At the pressurized galleys, a pipe plug port fed oil to the remote bypass oil filter. Once filtered, the cleaner oil returned through another line to the engine crankcase, sometimes via the timing cover like on vintage Jeep L- and F-head fours.

Upon engine teardown, the crankshaft and cam bearings in the bypass filter engines were always embedded with debris. Rod, crankshaft and camshaft bearings were designed to absorb this debris with a softer face or overlay layer. That layer exists in bearings to this day, a measure to protect the journals from damage.

1957-60 Ford F100 series pickups feature the base OHV inline 223 six with a full-flow, spin on oil filter. The filter can be seen below the distributor at the side of the block. At a 2005 car show, this specimen brought back plenty of memories.

To be clear, full flow filter engines are not thoroughly protected. Either the engine block or the filter itself has a bypass valve to move oil directly into the engine when the filter cannot pass oil through. This can be a clogged filter or when the engine is cold enough for the oil to stiffen, which can raise the differential pressure across the oil filter. Essentially, the oil pump is moving more oil than the filter can flow. Engines with full-flow filters exhibit their share of bearing damage on teardown. Poor maintenance, dirty oil and delayed filter changes can be a contributing factor.

The original Frantz filter used inexpensive, off the shelf toilet tissue as a filtration media. These filters could do a better job of filtration than the factory bypass systems. The micron filtration of dense tissue was more effective than the pleated paper media in a bypass filter cartridge or full-flow spin on filter canisters. Despite kidding about the toilet tissue media, the Frantz Oil Filter has been highly respected by DIY consumers, shop mechanics and truck fleet operators.

Frantz Filters have been used on every kind of lubricated engine application, whether equipped with or without an OEM full-flow filtration system. A Frantz filter can be the optimal add-on for engines that use a modern full-flow oil filter. LSI’s development of scientifically advanced filtration media has taken the Frantz oil filter into the modern era.

By design, even the best spin-on, full flow oil filter cannot filter down to 2 microns without opening the bypass valve. Once a full-flow filter bypasses due to clogging, stiff cold oil flow or high volume loads, unfiltered oil goes directly from the oil pump to the bearings. The only way to safely drop the micron filtration is through the use of a bypass oil filter system like the Frantz Filter, which will not interfere with engine oil flow. Shown here is the awkward Cummins oil filter location in our Ram. A desirable bonus with the Frantz Filter is an extended interval between the OEM full-flow oil filter changes.

The Frantz Oil Filter Extends Oil Life

Here is enough reason to install the Frantz Oil Filter kit on a modern diesel truck engine! The bypass filter can lower the micron filtration size way below that of a spin-on full flow filter. Cleaner oil is the result, as dramatically illustrated by this reputable independent test. (Illustration courtesy of Lubrication Specialties, Inc.)

Lubrication Specialties, Inc. Brings New Life to a Legacy Filtration Product

Lubrication Specialties, Inc. (LSI) acquired the Frantz Oil Filter company in 2014 and has dramatically improved this legacy product. LSI set out to modernize the filter media and take this legacy product to the next level with scientifically proven cellulose and synthetic filtration. LSI understood the shortcomings of a full-flow oil filtration system, mainly the more sizable debris and contaminants either passing through or bypassing the filter.

An OEM full-flow filter can bypass when the engine starts up cold, under high speed load demands or when the filter becomes clogged before an oil and filter change. There is no warning that the full-flow oil filter is bypassing. Oil pressure will remain constant whether oil can flow through the filter or not. Oil pressure is controlled by the pressure regulator valve at the oil pump or the entry passage into the lubrication system. When the filter’s bypass valve opens, oil continues to flow at a steady pressure past the filter.

For a full-flow filter to assure adequate oil supply to the bearings, the bypass valve in the OEM oil filter or the block can begin bleeding off at relatively low differential pressures across the filter. According to LSI research, these pressures can be as low as 3 PSI. An OEM filter’s bypass valve might be wide open at a 9 PSI differential pressure across the filter.

The micron filtration size of a full-flow oil filter is a trade-off between keeping the oil reasonably clean and providing the engine bearings with constant protection. By design and function, the full-flow oil filter must focus on larger particles. In contrast, the bypass approach of the Frantz Filter enables filtration down to a much smaller micron size while still not inhibiting normal engine oiling.

Unlike the full-flow oil filter, the bypass filter is not directly between the oil pump and bearings. As a result, the bypass Frantz Filter can clean far more thoroughly, at a much smaller micron level, than the engine’s full-flow filter. If the Frantz filter cartridge does clog, there is no impact on the engine’s normal oil flow or the OEM full-flow filtration system.

The Frantz Filter Kit, outlined in detail within the video, comes with options. The quality standard hose (blue at upper right) is suitable for most applications. For our installation, we opted for the stainless steel braided oil lines and extra quick couplers. For ideas, see the video details and our 2005 Ram Cummins 5.9L diesel step-by-step installation procedure.

We needed an open space for a mounting location. This looked promising but turned out to be an exceptionally hot area. The turbocharger and massive iron exhaust manifold generate steady heat. You could fry eggs above this manifold. We looked elsewhere for a suitable mounting location with space to dissipate the heat from the hot oil canister.

Mounting here at the firewall sill was ruled out due to the heat rising from the exhaust manifold and turbocharger housing. This was the only space available topside on our 2005 Gen 3 Ram Cummins. We turned next to the view below the engine and at the frame. The filter assembly needs dead air space and adequate room for hoses. Moving and flexing parts, electrical components, wiring and heat must be avoided.

This cast iron bracket for the A/C compressor has a flange suited for mounting our Frantz Filter bracket. Drilling and tapping these two holes is covered in the video. The location enables quick access to the filter assembly for service, not far from the OEM full-flow spin on filter. After following the installation steps, you can decide which location works for your installation. If you have room at the firewall, a fender well or safely at the frame, you can eliminate concern around engine vibration.

In position, the new Frantz Oil Filter is vertical. The couplers and braided lines feed upward to the oil pressure source above the OEM oil filter stand (the pressurized feed point) and to the oil filler cap (oil return into the valve cover). All parts are well crafted and durable, intended for a long service life. Mounted in this position, the filter is well out of harm’s way and does not interfere with the steering linkage or anti-sway bar. Service access for routine Frantz filter replacements will be simple and nearby the OEM filter location.

*Note: There is an update below on our Frantz Filter’s mount. This mounting location was our choice. While optimal for service access and air flow around the oil filter canister, our Frantz filter mounting point is subject to engine vibration. Below is how we addressed this issue.

Update on Mounting the Filter Assembly on the Engine: Fabricating a Solid Mounting Bracket

The bypass Frantz Oil Filter Kit for our Ram/Cummins 5.9L turbo-diesel truck came with a universal mounting bracket. The kit’s bracket is well suited for body or frame mounting.

We chose to mount the filter directly on the engine, much like a traditional OEM mount. Our choice required replacing the kit’s stainless steel bracket with a custom fabricated bracket constructed from weldable, mild steel plate. This video shows how-to steps for fabricating the new bracket. The approach will provide ideas for this kind of challenge and fabrication job.

Before this bracket update, we completed the in-depth video on the Frantz Oil Filter and our initial installation. (See the start of this post and the lead video.) For direct engine mounting, we needed a solid bracket. The video shows our use of 3-inch wide, 3/16″ thick, “weldable” mild steel as the solution. The new mount bolts at the same location as the kit’s stainless steel bracket.

Bypass Filtration Will Help Preserve the Cummins Engine

LSI offers two types of filter media for the Frantz filters: cellulose and synthetic. Cellulose is less expensive but offers excellent water retention. Synthetic will last two to three times longer, depending upon use and application. Both filtration media offer tremendous advantages in ultra-small micron filtration. See additional details in the video.

Clearly an OEM full-flow oil filter is a good idea. The factory filter catches larger, more menacing particles right out of the crankcase and oil pump. However, the micron filtration will not clean the oil well or offer the best engine bearing protection. Dirty oil calls for more frequent oil changes. On a diesel engine with an 11-quart crankcase plus the OEM filter fill (12 quarts total per oil and filter change), extending the oil change interval is a major savings. This is one reason why fleet operators install Frantz Oil Filters.

According to Blackstone Laboratories, an authority on engine oil requirements, engine oil becomes contaminated long before it wears out or loses effectiveness. This applies to any conventional or synthetic oil. The LSI focus has been improving overall performance through better oil filtration media. The latest Frantz Oil Filter media is scientifically engineered to pay for itself many times over by extending oil change intervals and improving engine protection.

We now use Fleetguard® StrataPore™ Venturi “Extended Life” oil filters on our Cummins 5.9L engine. Extending this full-flow filter’s life with the Frantz Filter bypass system will save significantly over time and help us reach our 500,000 to a million mile service life goal for the 2005 Gen 3 Ram Cummins 5.9L engine.

2 comments

I read with interest the article in Turbo Diesel Register Magazine about the Frantz oil filter by Moses Ludel TDR writer. I believe in by pass filters. Been using the Frantz since around the late 1960’s on my cars. There are a lot of stories I can tell about this filter. I am asking you to look at the FS2500 by pass filter, and maybe write an article on this by pass filter too. Been using this FS2500 since 2005 on my Ram and now using the same filter on my 2018 Ram. Think this FS2500 is a better quality, or better designed than Frantz.

Larry, thanks for your comments. The FS2500 looks like a very good unit and product. Its canister spin-on filter is easy to service as well. Your comments and personal experience are valuable to viewers considering a bypass oil filtration system…The Frantz Filter does work for me. LSI’s development of new filter media was the catalyst for my choosing the Frantz unit. Like your experience, mine dates to the late sixties, and I’m sure we had similar exposure the original Frantz Filter…I would like any viewer to consider the full range of products in the market. The FS2500 has a substantial mounting system, which would be less work than my fabricated mount for the Frantz unit. Please join us at the forums (https://forums.4WDmechanix.com) if you would like to compare notes further and share experiences.

Regards,

Moses