Add a Tail to your Fishbone Diagram: Improving Clarity with Root Cause Analysis

"Ok, now what?" A common question I received many times when working with new Green Belt Lean Six Sigma practitioners as they attempted to facilitate a Fishbone Diagram. Rightfully so. I remember my experiences with Fishbone Diagrams; they provide so much information, and yet, still create a haze of confusion on what to do next. The Fishbone Diagram (also known as an Ishikawa and/or Cause and Effect Diagram) allows your team to brain dump everything that impacts a process. But what then? What is the process to sift through those thoughts and start driving actions? Let me introduce you to my methodology, the Tailed Fishbone.

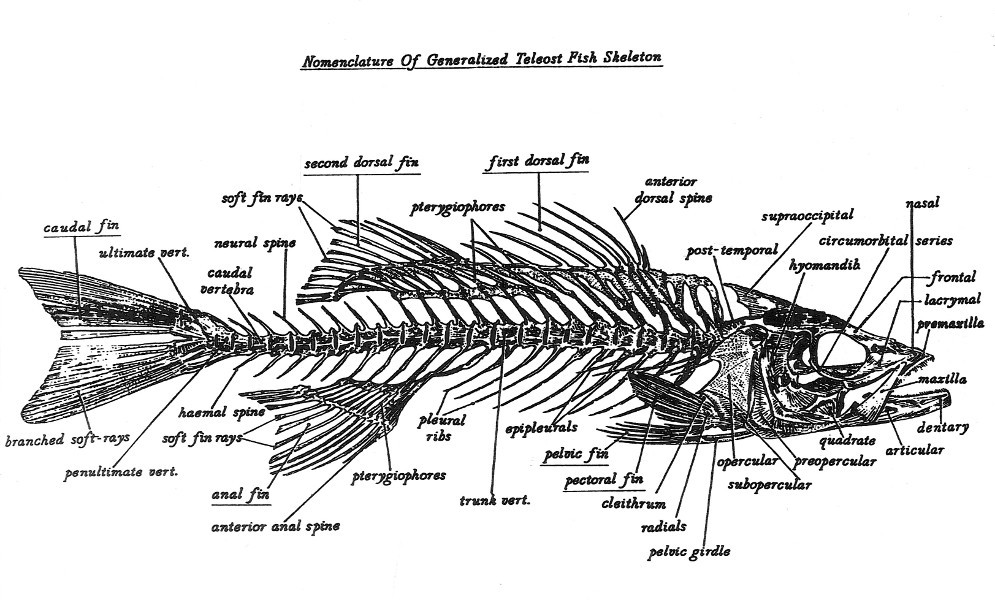

Before I share my model however, let's understand the traditional Fishbone Diagram first. Most Fishbone Diagrams will look like what you see here. This is a common example seen in many training rooms and Kaizen events. The Fishbone guides the thinker between potential failure modes from different categories. Categories such as Man, Method, Materials, and Machinery (i.e. the 4Ms) are the most common. As the tool became more popular, you started seeing it used in other industries, and with changing categories too.

What you do with that information next is the stumbling block for many. Some may choose to focus on all of the issues. Others have instituted voting to get to your vital few critical factors. What I've learned is these approaches can heavily bog down your team's action plans. Most plans have 3-4 actions required to implement one solution. Therefore, if you're going to establish a solution for each of the contributing factors, or even for the top 4, you could end up with an action plan that has 16 or more actions. This is quite a lot when team members have full-time jobs, plus work to catch up on while they were away brainstorming.

Using the Tailed Fishbone, you take it another step further and identify your number one critical contributing factor. This doesn't stop the process though. Instead, we will use this top critical contributing factor as our 1st Why in our 5-Why Analysis that makes up our Tailed Fishbone. Let me stop here and start showing you what I mean so far in a real-world example.

Scenario: A support organization had the responsibility to account for and maintain equipment for the using organization. However, when the support organization would look for the equipment based off where technicians said the equipment was installed, it turns out the equipment wasn't there. This caused technicians to stop performing maintenance and instead search for their missing equipment on a 1.6 square-mile flight line. It could take 3-4 hours to find one missing equipment, and days to conduct a complete audit.

What they found was the documentation of where their equipment was installed was typically inputted incorrectly into the computer system. The computer system had measures in place to prevent this if you used the wrong part and serial information, however, the computers had overrides that could allow for force loading of the information. These force loads occurred all the time and created havoc with accurate tracking and accountability. To tackle this problem, a team was put together, and we began by brainstorming a fishbone diagram.

The issues identified highlighted the team’s frustrations. They felt that people were not being held accountable for their poor processes, and that their leadership wasn't supporting them. This is very common with teams trying to solve a process problem. We know that Root Blame isn't going to fly with us, and at this stage we just want people brain dumping. Sometimes that means dumping your frustrations too. Also note there is one contributing factor in the starved Place category. Facilitator's prerogative here if you want to move it elsewhere, continue the brainstorming, or move forward with the next activity. We chose to move forward.

Here we let each person have 3 votes per category (People, Place, Process, and Product). As you can see, not everyone used all their votes. We allowed people to vote more than once on a single contributing factor within a category, but no more than three times. Therefore, with our team of 8, we can have up to 24 votes per category. Now, we look for our winners. This would be the "vital few" in most Fishbone Diagrams. But we do not end here.

Our 8-member team has had just one vote to spend on any of the four red circles. We have a winner with "Improper Documentation" and now it is time to start our 5-Why Analysis. The very first answer to Why we have a 25% error rate (our problem statement) will be the winner of the second round of voting (Improper Documentation).

It appears our technicians are saying that if the users of the equipment could read the part number after they install the equipment, they would no longer need cheat sheets when trying to input the part number (P/N) / serial number (S/N) combination into the computer tracking system, and that the documentation error for these pieces of equipment would cease to exist. We therefore placed this root cause into the Tail of our Fishbone thus creating the Tailed Fishbone.

The team decided they would stencil the Part Number (that previously wasn't visible once the equipment was installed) right above the serial number (which was visible after install).

After deciding this is the approach they wanted to take, but before they actually spent the time, energy, and resources to do so, we wanted to fact-check their solution against the Root Cause Analysis performed. We asked the question if the proposed solution would either Eliminate or Mitigate the contributing factor that led to our problem. The goal was to at least have the Root Cause solved for. Here's what they found as they put an X against each contributing factor they were able to eliminate / mitigate.

As you can see, they felt they could eliminate or mitigate 100% of their contributing factors leading to documentation errors that led to so many lost personnel hours of having to find equipment the computer said was in one place, but really wasn't. Here's how they did:

In summary, the Tailed Fishbone will allow you to focus your brainstorming efforts. This will help you navigate to a critical few, then to a critical one, to eventually a root cause. This will create focus not just in brainstorming, but problem solving, and action plans as well. The team above, besides updating their standard work and training on the new process, had a focused 3-action action plan that drove results. It’s both this type of outcome and ease that drives acceptance of process improvement in organizations.

For more information to include training slides I put together for the Tailed Fishbone, please see my presentation below:

Managing Director, McLean Management Consultants Pty Ltd

2yTo help this discussion, Dr Ishikawa's Guide to QC (1968) is my reference. You said this Mark "The Fishbone Diagram (also known as an Ishikawa and/or Cause and Effect Diagram) allows your team to brain dump everything that impacts a process. But what then? What is the process to sift through those thoughts and start driving actions?". So ''let me introduce you' all to Dr Ishikawa's "Process Classification Cause Enumeration Diagram" pp 24. Or as Don Dewar QCI International Ca USA, taught me in 1982 a "Process Cause Effect" (Chapter 7 Leader Manual 1984). Secondly as per the Toyota and GM and Jaguar LR adopted "Practical Problem Solving Methodology (7 or 8 steps - depends of course, See J Liker "Toyota Way" fig 20.3); the Industrial Engineering / Work Simplification '5-why' is asked against the Direct Cause (many times). This as even J Liker says in same book p254 "before 5-why you must Grasp the Situation". The ranked causes guide Data Collection to determine if it was a Symptom or a Root Cause. Various SPC graphs and charts help in this attribute and variable historical and actual cause analysis. I think these authors provide deep insights and learnings for us all, even today in this LinkedIn Social Media world. As I was taught in American Supplier Institute by Mike Anleitner and by Don Dewar earlier, it helps one get it "Right the First Time".

Retired Global Quality, EHS & Operations Leader

4yNice piece of work, well done .

Lean Manufacturing ✓ Program Management ✓ Operations Management ✓ Six Sigma Greenbelt ✓ At GE Appliances

4yThanks for sharing Mark!!

Sr. Manager Commercial Operations and Channel Distribution

4yChristina Laczko

Career Coach @Wonsulting | Workshop Facilitator | Black Belt Continuous Improvement Coach | Co-Founder of star6agency | Talent Optimization Consultant | RPR

4yGreat approach to prioritize outcomes and actions from the fishbone. I will adopt this and apply in my next session.