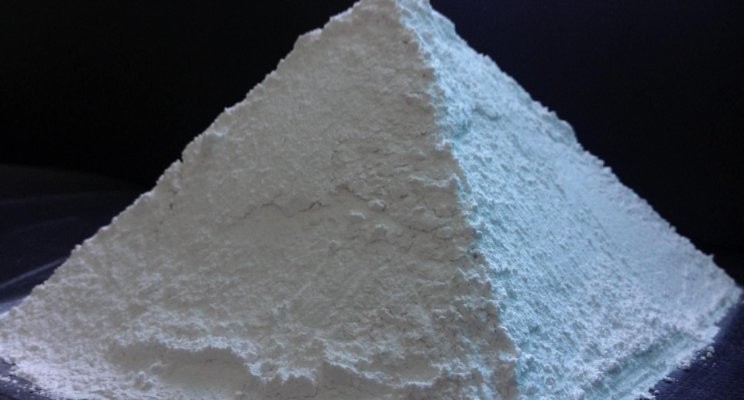

Uses of Talc

Talc is a clay mineral composed of hydrated magnesium silicate. It is a metamorphic mineral that results from the metamorphism of magnesian minerals such as serpentine, pyroxene, amphibole, and olivine, in the presence of carbon dioxide and water, and is practically insoluble in water and in weak acids and alkalis. It is used in many industries, including paper making, plastic, paint and coatings, rubber, food, electric cable, pharmaceuticals, cosmetics, and ceramics. Followings are uses of Talc in several industries.

Talc in Plastics

Talc imparts a variety of benefits to polypropylene, for instance higher stiffness and improved dimensional stability. Talc is mainly used as a filler in plastics. The platy shape of talc particles can increase the hardness of products such as polypropylene, vinyl, polyethylene, nylon, and polyester. It can also increase the heat resistance of these products and reduce shrinkage.

Talc in Ceramics

Talc is used in the manufacturing of ceramics products such as bathroom fixtures, ceramic tile, pottery, and dinnerware. When used as a filler in ceramics, talc can improve thermal shock resistance and the strength of the finished product. During firing, the talc is transformed into enstatite, which possesses electro-insulating properties. As for very low iron content talcs, they are particularly suitable for use in frit, engobe and glaze compositions.

Talc in Paint

Talc confers a whole range of benefits to coatings. In interior and exterior decorative paints, they act as extenders to improve hiding power and titanium dioxide efficiency. The platy shape of talc particles improves the suspension of solids in the can and helps the liquid paint adhere to a wall without sagging. Powdered talc is a very bright white color. This makes talc an excellent filler in paint because it simultaneously serves to whiten and brighten the paint. In anti-corrosion primers, talc is used to improve corrosion resistance and paint adhesion.

Talc in Paper

Talc used in paper improves printability as well as reducing surface friction, giving substantial improvements in productivity at the paper mill and print house. Finely ground mineral matter is added to the pulp to serve as a filler. When the pulp is rolled into thin sheets, the mineral matter fills spaces between the pulp fibers, resulting in a paper with a much smoother writing surface. Talc as a mineral filler can improve the opacity, brightness, and whiteness of the paper. Talc also can also improve the paper's ability to absorb ink.

Talc in Cosmetics and Antiperspirants

Finely ground talc is used as the powder base of many cosmetic products, providing the silkiness in blushes, powder compacts and eye shadows. Talc has the ability to absorb oils and perspiration produced by human skin. The ability of talc to absorb moisture, absorb odor, adhere to the skin, serve as a lubricant, and produce an astringent effect in contact with human skin make it an important ingredient in many antiperspirants. Soap manufacturers also use talc to enhance skin care performance.